Проектно-компонуемые БСУ

Группа компаний "ЭЛТИКОН" предлагает проектно-компонуемые БСУ производительностью от 40 до 320 м3/час. Количество смесителей от 1 до 4.

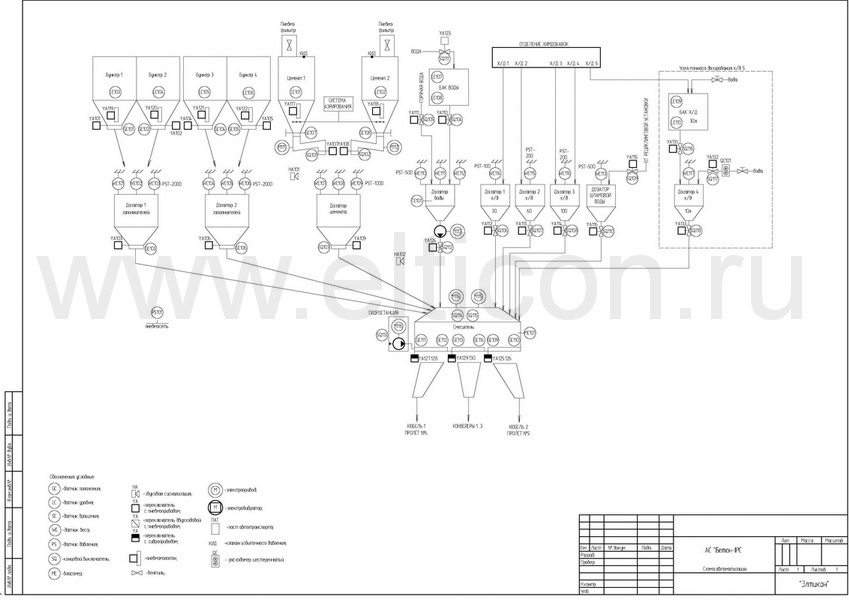

Автоматизированная система управления реконструированного БСУ АС "Бетон-IPC/СКБ-2"

Приготовление бетонной смеси - ключевой этап технологического процесса изготовления бетонных и железобетонных изделий, от которых зависит их надежность и долговечность. Условия приготовления бетонной смеси на существующем оборудовании не позволяют обеспечить достаточное качество приготовления и стабильность свойств получаемого бетона. Отсутствие контроля состояния загрузочно-выгрузочного устройств, неудовлетворительное состояние дозирующего оборудования, обеспечиваемая точность дозирования, отсутствие какой-либо информации о состоянии бетонной смеси приводит не только к случайному обеспечению необходимых показателей, но и к аварийным ситуациям. При дозировке и выгрузке составляющих бетона возможны ошибки оператора, несанкционированное срабатывание оборудования и образование брака. Отсутствие оценки свойств заполнителей (влажности) приводит к большому разбросу показателей особенно по консистенции.

Для компенсации неоднородности свойств возникает необходимость увеличения расхода цемента для обеспечения прочностных показателей приготавливаемой бетонной смеси.

Кроме всех технических проблем обеспечения технологического процесса существует проблема условий труда. По состоянию запыленности среды, уровню шума, вибрации условия работы не соответствуют санитарным нормам для производственных помещений.

Реконструкция бетоносмесительного цеха с устранением вышеперечисленных недостатков (заменой дозирующего оборудования, устройством системы приготовления подачи и дозирования добавок, автоматизации управления приготовлением бетонной смеси и др.) позволит обеспечить стабилизацию свойств бетонной смеси при ее приготовлении без значительных капитальных затрат и в короткие сроки.

Основа КТС АС "Бетон-IPC/СКБ-2" - промышленный компьютер Микро РС, расположен в шкафу управления отдельным блоком и совмещен с модулями ввода-вывода дискретных и аналоговых сигналов (УСО). В совокупности все модули электроники составляют технологическую станцию компьютерного контроля и управления.

Основные технические данные и характеристики

| Наименование | Показатель |

| Входное напряжение питания переменным током промышленной частоты 50 Гц, В | 187,0 … 242,0 |

| Выходное напряжение питания цепей тензометрических датчиков силы стабилизированным напряжением постоянного тока, В | 5,0 ± 0,01 |

| Выходное напряжение питания цепей бесконтактных датчиков напряжением постоянного тока, В | 20,4 …27,6 |

| Выходное напряжение цепей управления исполнительными механизмами («Сеть ИМ»), В | 187,0 … 242,0 |

| Потребляемая мощность, кВт | не более 0,75 |

| Система взвешивания | Тензометрическая |

| Адаптация к скоростям истечения материалов и задержкам срабатывания затворов | Автоматическая |

| Учет результатов работы | Автоматический |

| Наибольшие пределы взвешивания тензометрических каналов измерения веса: | |

| - дозаторы заполнителей, кг | 1600 |

| - дозатор цемента, кг | 600 |

| - дозаторы химдобавок, кг | 60 |

| - дозатор извести, кг | 600 |

| Погрешность статического взвешивания тензометрическими каналами измерения веса: | |

| - заполнители, кг, не хуже | ±1,6 |

| - цемент, кг, не хуже | ±0,6 |

| - химдобавки, кг, не хуже | ±0,03 |

| - известь, кг, не хуже | ±0,4 |

| Среднее время наработки на отказ, часов, не менее | 10 000 |

| Полный средний срок службы, лет | не менее 10 |