АСУ ТП на Волгоградском заводе органо-минеральных удобрений

Автоматизированная система управления «Композит/ОМУ-166» была внедрена компанией ЭЛТИКОН на Волгоградском заводе органоминеральных удобрений в апреле 2006 года.

Основным компонентом производимых на данном заводе удобрений является термически высушенный куриный помет.

Использование термической сушки куриного помета позволяет:

- сохранить в нем наибольшее количество полезных веществ;

- полностью уничтожить все болезнетворные микроорганизмы;

- произвести стерилизацию находящихся в помете семян растений;

- удалить избыточную влагу, чтобы сделать продукт пригодным для длительного хранения.

Технически высушенный куриный помет является комплексным, стерильным и высокоэффективным органическим удобрением, содержащим в легко доступной для растений форме азот, фосфор, калий, магний, кальций, серу и необходимые микроэлементы (всего более 10).

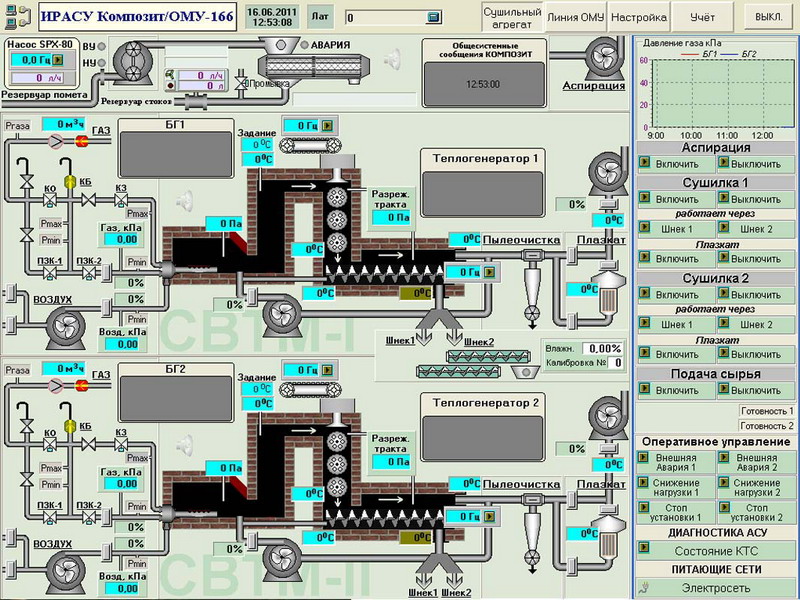

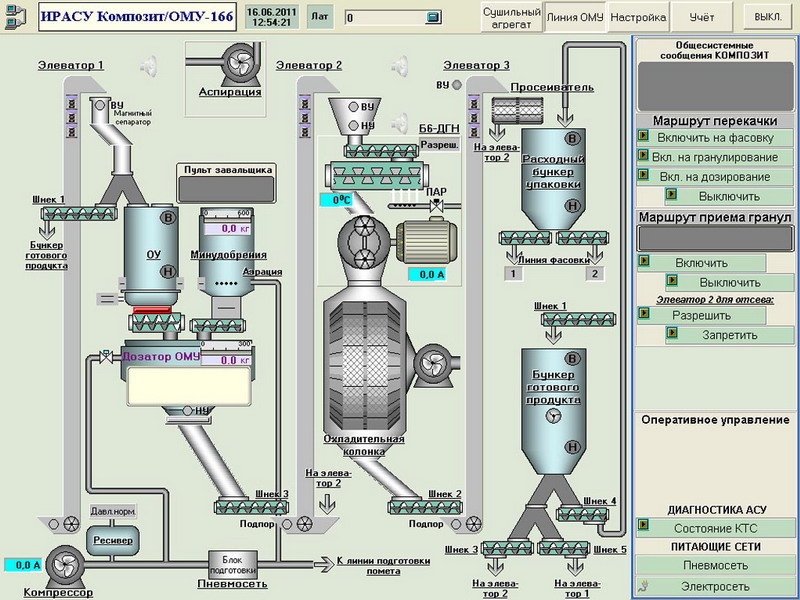

АСУ «Композит/ОМУ-166» позволяет контролировать:

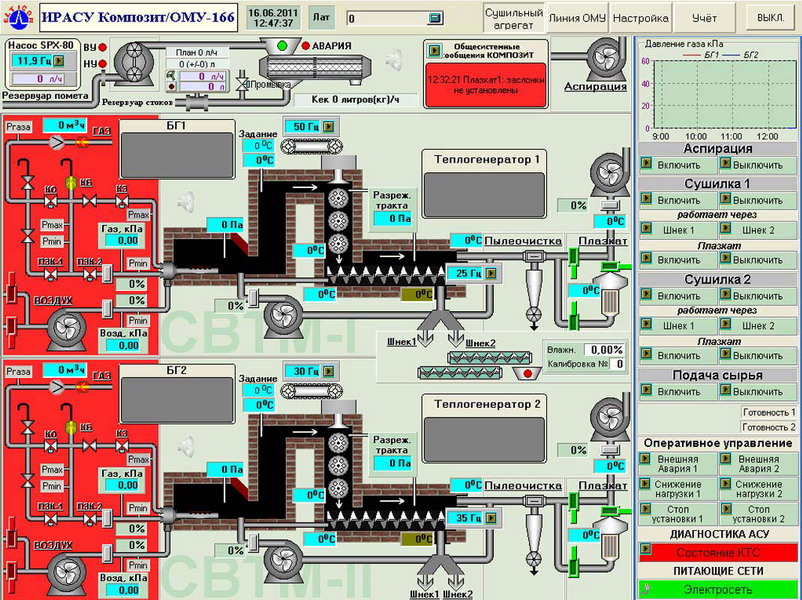

- процессы сушки и аспирации, в том числе работу насосов резервуара куриного помета и аспирации, теплогенераторов с воздухоподающими и вытяжными насосами (рис.1),

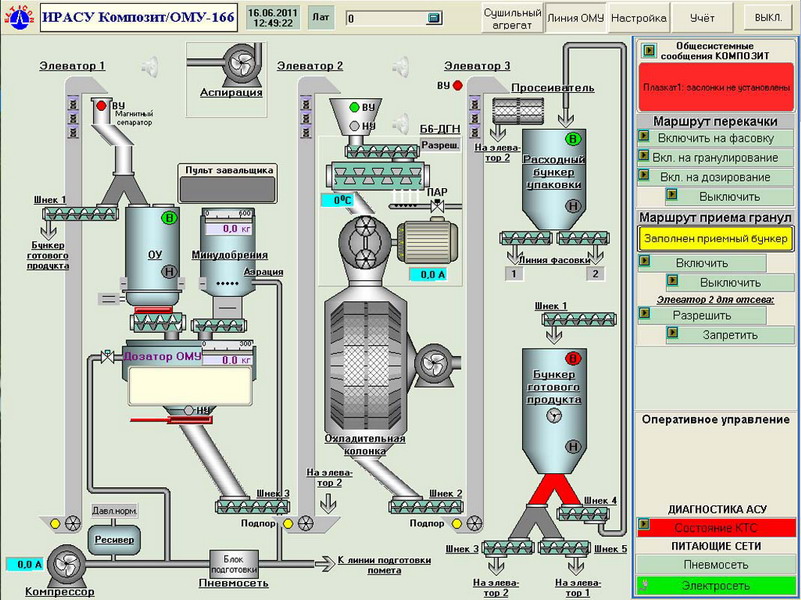

- процессы загрузки бункеров органоминеральных удобрений (рис.2),

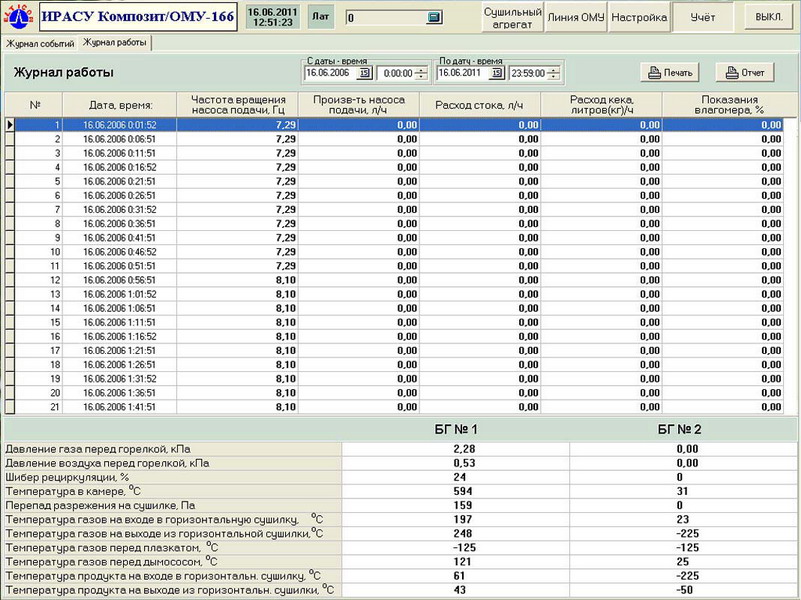

- а также производить учет работы механизмов, материалов, продукции и ресурсов (рис.3).

Система предусматривает режимы диагностики и индикации неисправностей работы оборудования и нарушений технологии производственного процесса производства удобрений (рис.4, рис.5).