Дорожно-строительная отрасль

Задачи повышения качества продукции и эффективности использования производственных мощностей и ресурсов являются первоочередными для любого производства, в том числе и для заводов, производящих асфальтобитумные и бетонные смеси.

Задачи повышения качества продукции и эффективности использования производственных мощностей и ресурсов являются первоочередными для любого производства, в том числе и для заводов, производящих асфальтобитумные и бетонные смеси.

Износ и старение производственного оборудования, его несоответствие современным требованиям по производительности, энергосбережению, качеству продукции, безопасности и защиты окружающей среды, а также обилие ручных операций выявляют необходимость в реконструкции, модернизации и автоматизации, как отдельных узлов, так и завода в целом.

Грамотная автоматизация, учитывающая индивидуальные особенности производства, позволяет достичь максимальной производительности при сохранении требуемого качества и снижении затрат на энергоресурсы и материалы.

Большинство асфальтобетонных заводов в странах СНГ имеют устаревшую автоматику и компания «ЭЛТИКОН» предлагает им модернизацию производства с учетом существующего оборудования, при значительной экономии средств за счет использования части узлов и комплектующих производства стран СНГ, в соответствии с ТУ ГОСТ 27945. При этом, в отличии от большинства конкурентов, в решениях компании «ЭЛТИКОН» используется пониженное питание датчиков (24В), что является важным фактором безопасности при работе на отрытом воздухе.

Компанией ЭЛТИКОН успешно разработано полнокомплектное решение в области дорожно-строительной отрасли, а именно:

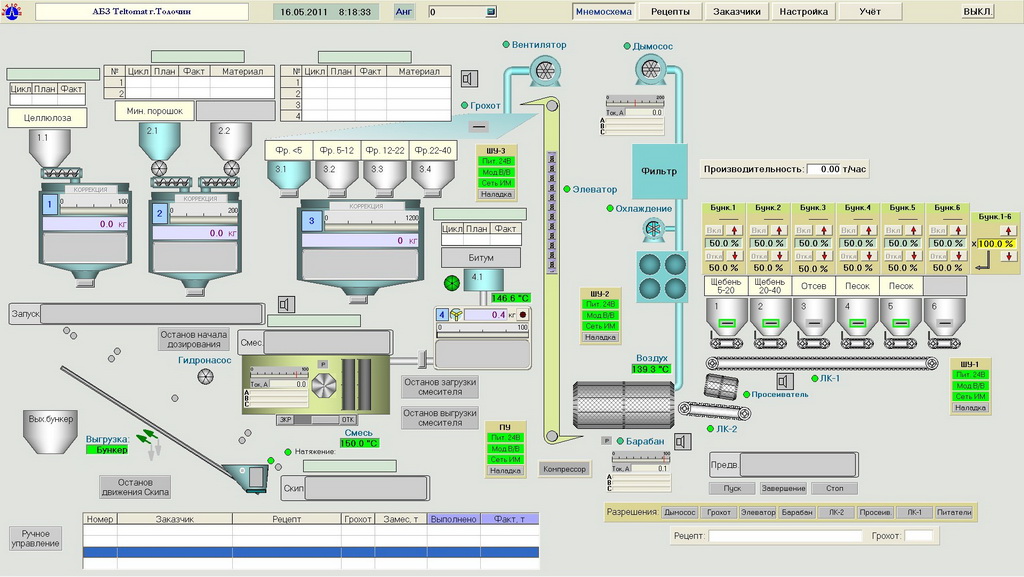

АТК асфальто-бетонного завода

Данный автоматизированный тестовый комплекс успешно зарекомендовал себя в работе как надежный и современный продукт, который позволяет существенно повысить эффективность производства и уменьшить финансовые издержки предприятий.

При решении задач реконструкции и модернизации существующих асфальтобетонных заводов ООО «ЭЛТИКОН» проводит полный комплекс работ, включая: выезд на объект, обследование, разработку документации и рекомендаций по модернизации, комплектование и поставку оборудования, шефмонтаж производственных линий и монтаж АСУ ТП, пуско-наладку, обучение и дальнейшее сопровождение.

Так, в конце 2010 года компания произвела полную замену АСУ ТП и части технологического оборудования асфальтосмесительной установки «ТЕЛЬТОМАТ» в городе Толочин Витебской области.

В результате проведенных работ полностью автоматизированы сквозные процессы приготовления и отгрузки асфальтобетонной смеси, что позволило исключить ошибки дозирования составляющих ее компонентов и обеспечить полный цикл работ без ручных операций.

Основные технические характеристики АСУ ТП «ТЕЛЬТОМАТ»

Обеспечивает управление и обработку сигналов для следующего оборудования:

1. Системы предварительного дозирования, в составе:

- питатели конвейерные шести бункеров наполнителей, управляемые преобразователями частоты с датчиками наличия материала и вентиляторами охлаждения двигателей;

- вибраторы шести бункеров наполнителей;

- сборный конвейер с датчиком вращения;

- наклонный конвейер с датчиком вращения;

- аварийные леера на конвейерах.

2. Сушильного барабана с системой вытяжки и горячим элеватором, в составе:

- электродвигатель сушильного барабана с фазовым ротором с устройством «плавного пуска» (контроль тока на каждой фазе);

- датчик температуры воздуха (выход из барабана);

- электродвигатель системы вытяжки;

- датчик разряжения в системе вытяжки;

- горячий элеватор с датчиком схода (обрыва) цепи;

- датчик температуры материала.

3. Системы сепарирования и основного дозирования, в составе:

- сепаратор;

- электро-гидро затворы четырех бункеров наполнителей;

- вибратор бункера пыли;

- ворошитель бункера пыли;

- шнековый питатель бункера пыли;

- ворошитель бункера минерального порошка;

- шнековый питатель бункера минерального порошка;

- шнековый питатель бункера целлюлозы;

- дозатор наполнителей;

- дозатор пыли и минерального порошка;

- дозатор целлюлозы;

- система подачи битума с импульсным счетчиком.

4. Смесителя, в составе:

- электродвигатель смесителя с фазовым ротором с устройством «плавного пуска» (контроль тока на каждой фазе);

- гидротолкатель системы выгрузки с датчиками положения (открыт/закрыт).

5. Системы транспортировки смеси, в составе:

- электродвигатель скипа, управляемый преобразователем частоты;

- тормоз скипа;

- датчики положения скипа;

- датчики провисания тросса;

- гидротолкатель стрелки рельсовой с двумя датчиками положения;

- аварийные датчики.

6. Бункера готовой смеси.

Режимы управления:

- автоматический - при выполнении заказов на производство и отгрузку асфальто-бетонных смесей в соответствии с ГОСТ 9128;

- автоматизированный - при вмешательствах оператора в работу системы, формировании рецептов, заданий на производство асфальто-бетонных смесей, просмотре и распечатке отчетов;

- ручной - с пультов местного управления, установленных по месту размещения оборудования для его опробования и наладки.

Функции программного обеспечения АСУ ТП:

- визуальное представление технологического процесса на графической мнемосхеме;

- управление технологическим процессом посредством интуитивно понятного интерфейса;

- ведение базы данных рецептов;

- производство асфальтобетонных смесей на основании базы данных рецептов;

- назначение компонент в бункерах предварительной дозировки;

- управления процессом предварительной дозировки на основании задаваемых оператором правил;

- назначение компонент в бункерах системы сепарирования и дозирования;

- ведение архива замесов с данными дозировок;

- вывод на экран и принтер отчетов по интересующему периоду о выполненных замесах, дозировках, расходе материалов;

- обеспечение автоматического резервного копирования базы данных;

- безаварийное завершение текущего выполняемого задания в случае непредвиденного разрыва связи с операторской станцией;

- автоматическое сохранение оперативных данных в энергонезависимой памяти при выключении питания.

Обеспечение безопасного управления оборудованием, необходимых блокировок и защиты, посредством:

- приостановки технологического процесса при возникновении любой аварийной или нештатной ситуации до подтверждения оператором возможности продолжить процесс;

- выдачи текстовых и условных звуковых и мнемонических (однозначно интерпретируемые) сообщений о причинах и характере аварийных и нештатных ситуаций до подтверждения оператором того, что он сообщения принял к сведению;

- штатного начала и продолжения технологического процесса после аварийных и нештатных ситуаций по указанию оператора с предпусковой сигнализацией;

- обеспечения необходимой последовательности включения и выключения механизмов, в том числе и в аварийных ситуациях;

- обеспечения защиты наиболее мощных механизмов от перегрузки по признакам превышения допустимой потребляемой мощности (тока) электроприводами или недостаточной скорости вращения, движения механизмов.

Погрешности дозирования компонентов асфальтобетонных смесей:

- для дозаторов наполнителей не хуже 3%;

- для дозаторов пыли, минерального порошка и целлюлозы не хуже 1.5%;

- для дозатора битума не хуже 1.5%.

Производительность линии до 100 тонн асфальтобетонной смеси в час.

Более подробную информацию можно получить у специалистов компании ЭЛТИКОН по телефону +375 17 258-63-33 или по электронной почте com@elticon.ru.